Toyota Prius timing chain

For the 2010 Toyota Prius (both Gen II and Gen III models, with the 1.8 L 2ZR‑FXE hybrid engine), here are the official torque specifications and installation details for the timing chain and related components:

⚙️ Camshaft Timing Sprocket & Gear

From the 2ZR‑FXE engine manual:

- Inlet & exhaust camshaft sprocket flange bolts: 54 N·m (40 ft·lbf) (workshop-manuals.com, charm.li)

🔧 Timing Chain Tensioner

The tensioner assembly uses two bolts:

- Timing chain tensioner nuts: 12 N·m (9 ft·lbf)

Vibration Damper Bolt

For the No. 1 vibration damper that preloads the chain:

- Chain damper bolts: 21 N·m (15 ft·lbf) (scribd.com)

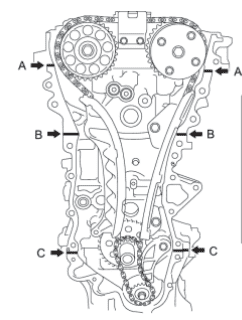

⛓️ Timing Chain Cover

Bolt torques vary by position:

- Bolts A, E, F: 26 N·m (19 ft·lbf)

- Bolts B, C: 51 N·m (38 ft·lbf)

- Bolt D: 10 N·m (7 ft·lbf) (charm.li)

📏 Bolt Torque Summary

| Component | Torque (N·m) | Torque (ft·lbf) |

|---|---|---|

| Cam sprocket flange bolts | 54 | 40 |

| Chain tensioner assembly nuts | 12 | 9 |

| Vibration damper bolts | 21 | 15 |

| Timing chain cover bolts (A,E,F / B,C / D) | 26 / 51 / 10 | 19 / 38 / 7 |

🔧 Installation Overview:

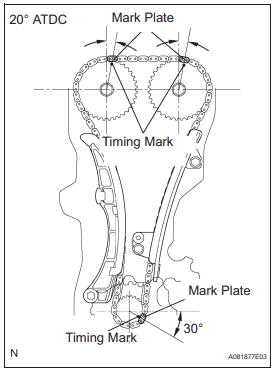

- Align cam sprockets and crank per factory match marks.

- Install chain vibration damper, torque to 21 N·m.

- Set tensioner plunger, then bolt the tensioner to 12 N·m.

- Secure the timing cover following the torque chart.

- Finish with the cam sprocket bolts torqued to 54 N·m.

🧰 Pro Tips & Community Notes

- The **tensioner is a common oil-seep point, though not always a failure; many Prius owners report mild seepage without needing full replacement (reddit.com, scribd.com, workshop-manuals.com, reddit.com, manualslib.com, reddit.com).

- Chain wear is uncommon—Prius timing chains are durable. A loose chain on inspection isn’t necessarily bad—tensioners often preload slack at first .

- If replacing the chain or tensioner, re-check timing marks carefully and torque bolts precisely as per the chart above.

📚 Additional Resources

- Factory torque specs from garage.wiki’s 2010 Prius engine guide (garage.wiki)

- Toyota workshop manual screenshots for sprocket and tensioner specs (workshop-manuals.com)

✅ Summary

For the 2010 Prius (2ZR‑FXE 1.8 L hybrid) timing chain assembly, the key torques are:

- Cam sprocket bolts: 54 N·m

- Tensioner nuts: 12 N·m

- Damper bolts: 21 N·m

- Timing cover bolts: 10–51 N·m by position

Proper bolt torque plus correct timing alignment ensures a reliable, smooth-running hybrid powertrain.

Toyota Prius 2010 timing chain manual PDF

Toyota Prius 2006 timing chain installation

Here’s a comprehensive guide for 2006 Toyota Prius (1NZ‑FXE 1.5 L hybrid, Gen I~II) timing chain installation, based on factory service manual specs and verified procedures:

🛠️ 1. Timing Chain Cover & Water Pump Bolts

Install evenly in several passes, following bolt length order:

| Bolt | Torque |

|---|---|

| A, C, E, G | 11 N·m (8 ft·lbf) |

| B, D, F | 24 N·m (18 ft·lbf) |

Additionally, after installing the cover, mounting bracket bolts: 55 N·m (41 ft·lbf) (workshop-manuals.com, charm.li).

- Cover installation must be completed within 3 minutes of applying sealant.

- Afterward, install the water pump and bracket within 15 minutes.

(id.scribd.com, workshop-manuals.com)

⛓️ 2. Chain Tensioner & Guide

- Tensioner/slipper bolt: 19 N·m (14 ft·lbf) (auto-master.su)

- Timing chain guide bolt (upper guide): 9 N·m (80 in·lbf) (auto-master.su)

🔧 3. Chain Vibration Damper & Oil Pump Sprocket

- Damper bolt: 9 N·m (80 in·lbf)

- Oil pump sprocket nut: 30 N·m (22 ft·lbf) (rotate crank +90° after) (justanswer.com)

🎛️ 4. Crankshaft Pulley & Sensor

- Crank pulley bolt: 128 N·m (94 ft·lbf) (workshop-manuals.com)

- Crank position sensor plate bolts: A: 7.5 N·m, B: 11 N·m (workshop-manuals.com)

✅ Installation Overview

- Align crank to TDC using crank key ▲ up.

- Fit the timing chain sub‑assembly: align colored link(s) to cam/crank sprocket marks.

(tcamanual.com) - Install oil pump sprocket and torque nut to 30 N·m, then rotate crank 90°.

(charm.li) - Fit tensioner slug/slipper guide—torque bolts: guide 9 N·m, tensioner 19 N·m.

(auto-master.su) - Mount vibration damper at 9 N·m.

- Install chain cover + pump, torque bolts per chart.

- Bolt down crank pulley to 128 N·m, then reinstall sensor and bracket at appropriate torques.

🧠 Special Notes

- After sealant is applied, all components must be installed within strict time frames to avoid seal failure.

(workshop-manuals.com, workshop-manuals.com) - Retain proper chain tension by supporting backlash on tensioner side.

- Rotate engine at least two full turns by hand to check timing marks realign & tensioner resets properly.

🧾 Summary Table

| Component | Torque |

|---|---|

| Cover bolts A, C, E, G | 11 N·m (8 ft·lbf) |

| Cover bolts B, D, F (incl. nut F) | 24 N·m (18 ft·lbf) |

| Mounting bracket | 55 N·m (41 ft·lbf) |

| Tensioner/slipper bolt | 19 N·m (14 ft·lbf) |

| Guide bolt | 9 N·m (80 in·lbf) |

| Chain damper bolt | 9 N·m (80 in·lbf) |

| Oil pump sprocket nut | 30 N·m + 90° turn |

| Crank pulley | 128 N·m (94 ft·lbf) |

| Sensor plate bolts A/B | 7.5 / 11 N·m |