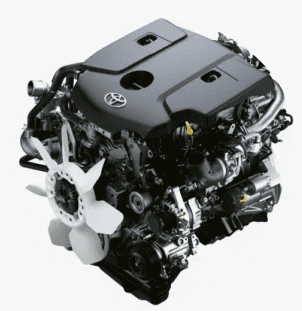

Toyota 2KD engine repair manual PDF free download

The Toyota 2KD engine is a 2.5L 4-cylinder diesel engine commonly found in vehicles like the Toyota Hilux, Fortuner, and Land Cruiser Prado. If you’re facing issues with the 2KD engine and need repairs, here’s a general guide to help you out:

1. Common Problems with the 2KD Engine

- Injector Problems: Clogged or faulty fuel injectors can cause misfires, poor fuel economy, and rough idling.

- Turbocharger Failure: The turbo can wear out over time, leading to reduced engine performance, loss of power, and blue smoke from the exhaust.

- Timing Chain Issues: Over time, the timing chain can stretch or break, causing engine misalignment and catastrophic engine failure if not addressed.

- EGR Valve Clogging: The Exhaust Gas Recirculation (EGR) valve can become clogged with carbon deposits, leading to poor engine performance and higher emissions.

- Oil Leaks: The 2KD engine may develop oil leaks, often around the timing cover, oil filter housing, or the valve cover.

- Head Gasket Failure: The head gasket can fail due to high engine temperatures, leading to coolant mixing with oil or coolant leaks.

2. Diagnostic Steps Before Repair

- Scan for Error Codes: Use an OBD-II scanner to check for error codes that may point to specific issues, like injector problems or sensor malfunctions.

- Check Oil and Coolant: Ensure the oil is clean and at the right level, and check the coolant for contamination.

- Inspect the Turbo: Look for signs of oil leaks around the turbocharger, unusual noise, or lack of boost.

- Compression Test: This will help determine the health of the pistons and valves, ensuring they’re sealing properly.

3. Repair Steps

- Fuel Injectors: If the injectors are faulty, they will need to be cleaned or replaced. If you are experiencing issues like smoke or poor performance, it might be due to one or more injectors malfunctioning.

- Turbocharger Repair/Replacement: If the turbo is damaged, it may need to be rebuilt or replaced. Turbochargers are expensive, so check for any possible leaks in the system first (e.g., intercooler or piping).

- Timing Chain: Replacing the timing chain is labor-intensive and typically requires the engine to be partially disassembled. If the chain is stretched or misaligned, it’s important to replace it to prevent major engine damage.

- EGR Valve Cleaning: A clogged EGR valve can be cleaned using an EGR cleaner or replaced if severely damaged.

- Head Gasket Replacement: If the head gasket is leaking, you will need to replace it, which typically involves removing the cylinder head, cleaning the surfaces, and installing a new gasket.

4. Maintenance Tips to Prevent Future Problems

- Regular Oil Changes: Diesel engines like the 2KD require clean, high-quality oil to run smoothly. Stick to the recommended oil change intervals.

- Fuel System Maintenance: Use high-quality fuel, and consider adding a diesel fuel additive periodically to clean the injectors and fuel lines.

- Keep an Eye on the EGR System: The EGR system should be cleaned every 100,000–150,000 km (or as recommended) to prevent carbon buildup.

- Turbo Maintenance: Ensure the turbocharger is working efficiently by monitoring boost levels and checking for oil leaks. Don’t drive the vehicle aggressively right after startup to allow proper turbo cooling.

5. Cost of Repair

The cost of repair for the 2KD engine can vary depending on the issue:

- Injector Replacement: Typically costs between $200–$600 per injector, depending on whether you repair or replace.

- Turbo Replacement: Can range from $600 to over $1,500 depending on the make and model.

- Head Gasket Replacement: Generally in the range of $500 to $1,500, depending on labor costs and whether the cylinder head needs resurfacing.

- Timing Chain: This can be quite expensive in terms of labor, costing anywhere from $500 to $2,000 for parts and labor.

6. Tools Needed for Repair

- OBD-II Scanner (for diagnostics)

- Socket set and wrenches

- Torque wrench

- Timing tools (for timing chain replacement)

- Injector cleaning kit (if applicable)

- EGR cleaner

- Gasket scraper

If you’re tackling the repair yourself, be sure to follow the vehicle-specific repair manual for torque specs, procedures, and part numbers.

Toyota 1HZ engine repair manual PDF

Repairing the Toyota 1HZ engine, a legendary 4.2L inline-6 diesel, involves careful handling due to its robust but aging mechanical design. This engine is popular in Toyota Land Cruiser models (like the 70 and 80 Series), known for durability, but issues like overheating, injector wear, or valve train noise can arise over time.

🔧 Common Toyota 1HZ Engine Repairs

1. Cylinder Head Issues

- Symptoms: Overheating, white smoke, coolant loss.

- Fix: Remove and inspect the head. Replace gasket or skim/replace the head. Use a torque wrench for proper reinstallation:

- Head bolt torque (final stage): 103 Nm (76 ft-lb) in correct sequence.

2. Fuel Injection System

- Symptoms: Hard starting, rough idle, black smoke.

- Fix:

- Check and clean injectors.

- Consider replacing nozzles or refurbishing the pump.

- Diesel injection pump must be timed precisely (0° BTDC at No. 1 cylinder compression).

3. Timing Belt Replacement

- Recommended every 100,000 km.

- Use OEM belt, and align camshaft/crankshaft properly.

- Torque spec:

- Tensioner bolt: 43 Nm (32 ft-lb)

4. Valve Adjustment

- Should be done every 40,000 km or if there’s noisy valve clatter.

- Cold clearance:

- Intake: 0.20 mm

- Exhaust: 0.35 mm

5. Glow Plug System

- Symptoms: Hard cold starts.

- Fix: Test each glow plug with a multimeter; replace if resistance is too high.

6. Oil Leaks

- Common from rocker cover, front/rear seals, and oil pan.

- Clean, reseal, and use new gaskets/O-rings.

🔩 Key Torque Specifications (1HZ Engine)

| Component | Torque Spec |

|---|---|

| Cylinder head bolts (final) | 103 Nm (76 ft-lb) |

| Connecting rod bolts | 59 Nm (44 ft-lb) |

| Main bearing cap bolts | 137 Nm (101 ft-lb) |

| Flywheel bolts | 167 Nm (123 ft-lb) |

| Camshaft bearing cap bolts | 14 Nm (10 ft-lb) |

🧰 Special Tools Recommended

- Valve spring compressor

- Diesel injector tester

- Torque wrench (digital or click-type)

- Feeler gauge

- Timing light for diesel (if electronic assist pump)

📘 Service Manual and Diagrams

I can help you find or summarize repair diagrams. Let me know if you want:

- A PDF service manual.

- Exploded diagrams (e.g., timing belt routing, head assembly).

- A step-by-step rebuild guide.

Toyota 4A FE engine repair manual PDF

Repairing the Toyota 4A-FE engine—a 1.6L inline-4 DOHC 16-valve fuel-injected engine—is a fairly common task for Toyota Corolla and Sprinter enthusiasts. It’s a strong, reliable engine from the late ’80s through early 2000s, but like all aging engines, it needs proper attention.

🔧 Common Toyota 4A-FE Engine Repairs

1. Cylinder Head Gasket Failure

- Symptoms: Overheating, white smoke, coolant in oil.

- Repair:

- Remove the head, inspect for warping or cracks.

- Replace with a high-quality MLS gasket.

- Torque Specs for Cylinder Head Bolts:

- Step 1: 39 Nm (29 ft-lb)

- Step 2: 90° turn

- Step 3: 90° turn (do this in proper sequence)

2. Timing Belt Replacement

- Should be done every 100,000 km (60,000 miles).

- Replace water pump at the same time (it’s driven by the timing belt).

- Torque Specs:

- Tensioner bolt: 43 Nm (32 ft-lb)

- Crank pulley bolt: 140 Nm (103 ft-lb)

- Belt alignment is critical. Align cam and crank timing marks exactly.

3. Valve Clearance Adjustment

- 4A-FE uses shim-over-bucket design.

- Rarely needs frequent adjustment, but if noisy:

- Intake: 0.15–0.25 mm (cold)

- Exhaust: 0.25–0.35 mm (cold)

- Requires removing the camshafts and using special tools to measure and replace shims.

4. Oil Leaks

- Common from:

- Distributor O-ring

- Camshaft oil seals

- Valve cover gasket

- Use new gaskets and clean mating surfaces.

5. Idle and Stalling Problems

- Clean the Idle Air Control Valve (IACV) and throttle body.

- Check for vacuum leaks and faulty coolant temperature sensor (ECT).

- Inspect MAF sensor (if equipped) and intake hose cracks.

6. Fuel Injector Issues

- Symptoms: misfire, poor fuel economy, hesitation.

- Remove and clean injectors or replace.

- Check fuel pressure with a gauge:

- Spec: ~38–44 psi (with vacuum hose disconnected from regulator)

🧰 Essential Torque Specs

| Part | Torque |

|---|---|

| Cylinder head bolts (step 1) | 39 Nm (29 ft-lb) |

| Cylinder head bolts (step 2/3) | 90° + 90° turn |

| Camshaft cap bolts | 13 Nm (115 in-lb) |

| Main bearing cap bolts | 60 Nm (44 ft-lb) |

| Rod cap bolts | 40 Nm (30 ft-lb) |

| Crankshaft pulley bolt | 140 Nm (103 ft-lb) |

| Flywheel bolts | 78 Nm (58 ft-lb) |

🛠️ Typical Tools Needed

- 10–22mm sockets and wrenches

- Torque wrench

- Feeler gauge

- Shim kit (for valve adjustment)

- Pulley puller

- Engine support bar (if removing mounts)

📘 Want a Full Repair Manual?

I can provide:

- Full engine rebuild guide (PDF)

- Exploded diagrams for the timing system or cylinder head

- Printable torque spec chart

- Wiring diagrams (for EFI/ignition)

Toyota 1KD engine repair manual pdf

Repairing the Toyota 1KD-FTV engine—a 3.0L inline-4 turbocharged common rail diesel—is a frequent task for diesel mechanics and Toyota owners, especially in Hilux, Fortuner, and Land Cruiser Prado models (2001–2016). Known for power and efficiency, the 1KD can still develop issues like injector failure, turbo problems, or cracked pistons if poorly maintained.

🛠️ Common Toyota 1KD Engine Repairs

1. 🔥 Injector Issues

- Symptoms: Knocking (diesel rattle), poor fuel economy, excessive black smoke, hard starting.

- Causes: Injector wear, carbon build-up in copper washers, incorrect pilot injection.

- Fix:

- Replace or refurbish injectors (Denso).

- Replace injector seats and seals (use genuine copper washers).

- Relearn injector compensation codes using a scan tool.

- Check valve cover for oil leakage from injectors.

- ✅ Tip: Use correct torque and new washers every time.

- Injector hold-down bolt: 8 Nm

2. 💨 Turbocharger Failure

- Symptoms: Loss of power, whining noise, overboost/underboost errors.

- Fix:

- Check for shaft play.

- Replace or rebuild turbo.

- Clean the VNT actuator mechanism (if sticking).

- Check MAP sensor and vacuum hoses.

3. 🔧 Cracked Pistons

- Known Issue (especially 2007–2012 models).

- Symptoms: Blue/white smoke, low compression, blow-by gases, knocking.

- Fix:

- Remove the head and inspect cylinders.

- Replace pistons with updated OEM design (2013+ part numbers).

- Consider full engine rebuild.

4. 🌡️ Overheating / Cooling System

- Causes: Head gasket failure, clogged radiator, EGR cooler leaks.

- Fix:

- Replace thermostat, radiator, water pump if needed.

- Pressure test cooling system.

- Inspect and replace head gasket if combustion gases found in coolant.

5. ⚙️ Timing Belt Replacement

- Replace every 150,000 km.

- Use OEM belt and tensioner.

- Timing belt tensioner bolt torque: 43 Nm

- Crankshaft pulley bolt torque: 280 Nm

🧰 1KD-FTV Torque Specs

| Component | Torque |

|---|---|

| Cylinder head bolts | 39 Nm + 90° + 90° |

| Injector hold-down bolts | 8 Nm |

| Connecting rod bolts | 54 Nm + 90° |

| Main bearing cap bolts | 120 Nm + 90° |

| Camshaft bearing cap bolts | 14 Nm |

| Crank pulley bolt | 280 Nm |

| Flywheel bolts | 108 Nm |

🧪 Important Diagnostics

- Scan DTCs using Techstream or equivalent scan tool.

- Check:

- Fuel pressure (Common rail: ~35–160 MPa depending on load)

- EGR system function

- MAF/MAP sensor readings

- Injector feedback values (±3.0 mm³/st acceptable range)

⚠️ Known 1KD Issues

| Problem | Recommended Fix |

|---|---|

| Piston cracking | Use updated pistons (2013+), avoid chip tuning |

| Injector knock | Replace injectors and washers |

| EGR clogging | Clean EGR valve and cooler |

| Blow-by/oil leaks | Replace PCV valve, piston rings |

| White smoke on cold start | Replace faulty glow plugs or injectors |

📘 Want More?

I can provide:

- 🧾 Full PDF service manual

- 🔩 Rebuild guide with all torque specs

- 🖼️ Exploded diagrams for injectors, pistons, timing system

- ✅ Injector compensation code how-to

Toyota 3S FE engine repair manual pdf

Repairing the Toyota 3S-FE engine—a 2.0L inline-4 DOHC fuel-injected engine from the legendary S-series—is a common task for mechanics and enthusiasts working on older Camry, Celica, Corona, and RAV4 models (1986–2001, depending on market). Known for its reliability, it still requires attention to aging parts like the head gasket, timing belt, and valve seals.

🔧 Toyota 3S-FE Engine Repair Overview

🛠️ 1. Head Gasket Failure

- Common on high-mileage engines.

- Symptoms: Overheating, coolant loss, white smoke, mixing oil/coolant.

- Repair:

- Remove cylinder head, inspect for warping.

- Replace with MLS gasket (OEM or equivalent).

- Check for cylinder head cracks near exhaust valves.

- Torque Specs (Head Bolts):

- Step 1: 49 Nm (36 ft-lb)

- Step 2: Loosen all bolts

- Step 3: 49 Nm again

- Step 4: +90°

- Step 5: +90° again

- Use correct torque sequence (center outwards spiral).

⏱️ 2. Timing Belt Replacement

- Every 100,000 km (60,000 mi).

- Also replace:

- Water pump

- Timing tensioner

- Cam/crank seals

- Torque Specs:

- Camshaft pulley bolt: 49 Nm

- Crankshaft pulley bolt: 160 Nm

- Idler/tensioner bolts: 43 Nm

💨 3. Valve Stem Seal Replacement

- Symptoms: Blue smoke on startup, oil consumption.

- Fix:

- Remove camshafts and valve springs.

- Use compressed air + valve spring compressor to replace seals in-place.

- Valve Clearance (cold):

- Intake: 0.15 – 0.25 mm

- Exhaust: 0.25 – 0.35 mm

🔌 4. Ignition System Problems

- Common issues:

- Distributor failure (leaking oil)

- Ignition coil breakdown

- Worn spark plugs or wires

- Fix:

- Replace distributor cap/rotor/coil.

- Use NGK or Denso plugs (gap: 1.1 mm)

- Spark plug torque: 18–22 Nm

🔧 5. Oil Leaks

- Frequent from:

- Valve cover gasket

- Camshaft seals

- Crankshaft seals

- Always replace seals when doing timing belt.

🧪 6. Idle Problems or Stalling

- Clean:

- Idle Air Control Valve (IACV)

- Throttle body

- EGR valve (if present)

- Check:

- Vacuum hoses for leaks

- Coolant temp sensor (affects cold start)

🔩 Common Torque Specs – Toyota 3S-FE

| Component | Torque |

|---|---|

| Cylinder head bolts | 49 Nm + 90° + 90° |

| Main bearing cap bolts | 64 Nm + 90° |

| Connecting rod bolts | 43 Nm |

| Crankshaft pulley bolt | 160 Nm |

| Camshaft cap bolts | 14 Nm |

| Spark plugs | 18–22 Nm |

| Intake/exhaust manifold nuts | 40–45 Nm |

| Flywheel bolts | 78 Nm |

🔧 Special Tools You May Need

- Valve spring compressor

- Torque angle gauge

- Pulley holder (for crankshaft bolt)

- Shim kit (for valve adjustment)

- OBD1 scanner (if using early EFI versions)

📘 Want More Help?

I can provide:

- 📥 Toyota 3S-FE full service manual (PDF)

- 🖼️ Timing belt diagram

- 🛠️ Rebuild checklist + parts list

- ⚙️ Vacuum diagram

- ✅ Diagnostic flowchart for idle, ignition, or misfire issues

Toyota 5A FE engine repair manual PDF

Repairing the Toyota 5A-FE engine—a 1.5L DOHC 16-valve fuel-injected inline-4—is a straightforward job for those familiar with Toyota’s A-series engines. It’s commonly found in vehicles like the Toyota Corolla, Sprinter, and Carina (mainly in Asian markets), and is a smaller sibling to the 4A-FE, built for fuel efficiency and long life.

🔧 Toyota 5A-FE Engine Repair Overview

⚠️ COMMON ISSUES

| Problem | Likely Cause / Fix |

|---|---|

| Overheating | Blown head gasket, faulty thermostat, clogged radiator |

| Oil leaks | Valve cover gasket, cam/crank seals, oil pan |

| Hard starting / poor idle | Dirty throttle body or IAC valve, faulty ECT sensor |

| Blue smoke on startup | Worn valve stem seals |

| Misfire / rough running | Worn spark plugs, bad ignition coil or distributor |

🛠️ Top Repairs & Procedures

1. Head Gasket Replacement

- Symptoms: White smoke, overheating, coolant in oil

- Fix:

- Inspect and skim head if warped.

- Replace gasket with OEM or metal multi-layer steel (MLS).

- Torque Specs for Head Bolts:

- Step 1: 39 Nm (29 ft-lb)

- Step 2: 90°

- Step 3: 90° again (use torque angle gauge)

- Follow criss-cross tightening pattern from the center out.

2. Timing Belt Replacement

- Service interval: every 100,000 km or 60,000 miles

- Replace water pump, tensioner, cam/crank seals at the same time.

- Torque Specs:

- Crankshaft pulley bolt: 130–140 Nm

- Camshaft pulley bolt: 54 Nm

- Timing belt tensioner bolt: 43 Nm

3. Valve Adjustment (Shim Type)

- Adjust if:

- Noisy valve train

- Poor performance or idle

- Clearances (cold engine):

- Intake: 0.15 – 0.25 mm

- Exhaust: 0.25 – 0.35 mm

- Requires removing camshafts and using valve shims.

4. Oil Leak Repair

- Common locations:

- Valve cover gasket

- Camshaft seal

- Crankshaft seal

- Replace gaskets and seals using OEM parts.

- Clean mating surfaces thoroughly.

5. Idle & Stalling Fix

- Clean:

- Idle Air Control Valve (IACV)

- Throttle body

- Check:

- Vacuum hoses

- Coolant temp sensor

- EGR valve (if equipped)

🔩 Key Torque Specs for Toyota 5A-FE

| Component | Torque |

|---|---|

| Cylinder head bolts | 39 Nm + 90° + 90° |

| Camshaft cap bolts | 14 Nm |

| Main bearing cap bolts | 60 Nm + 90° |

| Rod bolts | 40 Nm |

| Crankshaft pulley bolt | 130–140 Nm |

| Flywheel bolts | 78 Nm |

| Spark plugs | 18–22 Nm |

⚙️ SPECIAL TOOLS NEEDED

- Torque wrench & angle gauge

- Pulley holder

- Feeler gauge (for valve lash)

- Valve shim kit

- OBD1 scanner (for diagnostics on older models)

📘 Want More Help?

I can provide:

- 🧾 Full Toyota 5A-FE service manual (PDF)

- 🖼️ Exploded diagrams for timing, head, ignition

- ✅ Maintenance checklist

- 🛠️ Printable torque chart

- 🧪 Diagnostic flow for poor idle, misfire, etc.

Toyota D4D engine repair manual pdf

Repairing a Toyota D-4D engine involves understanding its high-pressure common rail diesel system, variable geometry turbochargers, and emissions control systems like EGR, DPF, and injector compensation codes.

D-4D engines come in several variants (1CD-FTV, 2KD-FTV, 1KD-FTV, 1ND-TV, etc.), but all follow similar repair principles. They’re commonly found in models like Hilux, Fortuner, Corolla, Avensis, RAV4, and Land Cruiser Prado.

🔧 Common Toyota D-4D Engine Repairs

1. 🔥 Injector Problems

- Symptoms: Knocking, black smoke, rough idle, poor fuel economy.

- Fix:

- Replace injectors with new or reconditioned Denso units.

- Use correct copper washers and torque values.

- Perform injector compensation coding using Techstream or equivalent.

- Clean the valve cover area to prevent carbon buildup.

- ✅ Injector bolt torque: 8 Nm

2. 💨 Turbocharger Issues

- Symptoms: Power loss, overboost/underboost codes, black smoke.

- Fix:

- Check VNT actuator for sticking.

- Clean carbon buildup on vanes.

- Test boost pressure sensor and vacuum hoses.

- Replace or rebuild turbo if damaged.

3. 🌡️ EGR & Intake Manifold Clogging

- Symptoms: Loss of power, poor throttle response, excessive smoke.

- Fix:

- Remove and clean the EGR valve and intake manifold.

- Check for error codes like P0400 or P0401.

- Clean the MAP sensor while you’re at it.

4. 🛢️ DPF (Diesel Particulate Filter) Blockage

(Only in newer Euro 4/5 D-4D models)

- Symptoms: Limp mode, high fuel consumption, P2002 or P2463 codes.

- Fix:

- Attempt forced regeneration with scan tool.

- Replace pressure sensors.

- If clogged beyond repair, replace or clean DPF with professional service.

5. ⚙️ Timing Belt / Chain Replacement

- 1KD/2KD engines = Timing belt every 150,000 km.

- Newer 1GD-FTV/2GD-FTV = Timing chain (inspect, not regularly replaced).

- Replace belt along with tensioner, idler, water pump.

- Crankshaft pulley bolt torque: 280 Nm (for 1KD)

6. ⚠️ Cracked Pistons (Especially 1KD, 2005–2012)

- Symptoms: Low compression, oil use, blue/white smoke, knocking.

- Fix:

- Remove head and oil pan.

- Replace pistons with updated OEM design (2013+).

- Rebuild or replace engine if cylinder walls are damaged.

7. 💡 Glow Plug Failure

- Symptoms: Hard cold starts, white smoke at startup.

- Fix:

- Test resistance (should be under 1–2 ohms).

- Replace all glow plugs if any are faulty.

- Be careful not to break stuck glow plugs—use penetrating oil.

🧰 D-4D Common Torque Specs

| Component | Torque |

|---|---|

| Cylinder head bolts | 39 Nm + 90° + 90° |

| Injector clamp bolts | 8 Nm |

| Crankshaft pulley bolt | 280 Nm (1KD/2KD) |

| Glow plugs | 12 Nm |

| Camshaft bearing cap bolts | 14 Nm |

| Flywheel bolts | 108 Nm |

🔎 Important Diagnostic Tips

| Diagnostic Test | Normal Reading or Result |

|---|---|

| Rail Pressure (Idle) | ~30–35 MPa |

| Injector Feedback Value Range | ±3.0 mm³/stroke |

| MAF Sensor (Idle) | ~4–6 g/s |

| MAP Sensor at WOT | ~120–160 kPa |

| Compression Test (1KD example) | ~350–450 psi (cold) |

📘 Want More Help?

I can provide:

- 📥 Toyota D-4D Engine Repair Manual (PDF)

- 🔩 Torque spec chart

- 🛠️ Injector coding tutorial

- 🧪 Diagnostic flowchart (with OBD codes)

- 🖼️ Exploded diagrams (EGR, turbo, timing)

Toyota 1NZ FE engine repair manual PDF

Repairing the Toyota 1NZ-FE engine—a 1.5L DOHC inline-4 VVT-i engine—is common in models like the Toyota Yaris, Vios, Belta, Echo, and Prius (early models). It’s part of the NZ series known for fuel efficiency, durability, and compact design, but like any engine, it faces issues as it ages—especially oil consumption, timing chain noise, or valve cover leaks.

🔧 Toyota 1NZ-FE Engine Repair Overview

🔥 1. Excessive Oil Consumption

- Symptoms: Frequent low oil, blue smoke on acceleration.

- Causes: Worn piston rings or valve stem seals.

- Fix Options:

- Top-end refresh: Replace valve stem seals.

- Full rebuild: New piston rings, possibly pistons (especially on 2001–2008 models).

- Use updated OEM pistons/rings (Toyota released newer versions with better oil control).

- ✅ Use high-mileage 5W-30 oil if not yet rebuilt.

🔗 2. Timing Chain Noise

- Symptoms: Rattling at cold start, poor timing.

- Fix:

- Replace timing chain, guides, and tensioner.

- Inspect and clean VVT-i gear (variable cam timing unit).

- ✅ No timing belt – chain is lifetime-rated, but often stretches past 200,000 km.

🛠️ 3. Valve Cover Leak

- Symptoms: Oil leaking around spark plugs or engine block.

- Fix:

- Replace valve cover gasket and spark plug tube seals.

- Clean and reseal with RTV (corners of half-moons).

- Torque Spec: Valve cover bolts – 8.8 Nm

💨 4. Throttle Body / Idle Issues

- Symptoms: Unstable idle, stalling, or hesitation.

- Fix:

- Clean throttle body and Idle Air Control Valve (IACV) (if equipped).

- Reset ECU idle learning.

- Check for vacuum leaks and faulty MAF sensor.

🔌 5. Ignition Coil or Spark Plug Failure

- Symptoms: Misfire, poor fuel economy, P0300–P0304 codes.

- Fix:

- Replace faulty coil(s) – each cylinder has its own coil-on-plug.

- Use NGK or Denso Iridium plugs, gapped to 1.0–1.1 mm.

- Torque Spec: Spark plugs – 18–21 Nm

🔩 Toyota 1NZ-FE Key Torque Specs

| Component | Torque |

|---|---|

| Cylinder head bolts | 25 Nm → 90° → 90° |

| Crankshaft pulley bolt | 190 Nm |

| Camshaft cap bolts | 13 Nm |

| Valve cover bolts | 8.8 Nm |

| Connecting rod bolts | 27 Nm + 90° |

| Main bearing cap bolts | 44 Nm + 90° |

| Oil pan bolts | 9–10 Nm |

🧪 Common DTC Codes on 1NZ-FE

| Code | Meaning | Likely Fix |

|---|---|---|

| P0300–P0304 | Cylinder misfire | Coil, plug, injector |

| P0171 | System too lean | Vacuum leak, MAF, fuel pressure |

| P0420 | Catalyst system below threshold | Faulty catalytic converter or O2 sensor |

| P0012 | Cam timing over-retarded (VVT problem) | Dirty oil, faulty VVT solenoid |

🧰 Tools You’ll Need

- Torque wrench

- Feeler gauge (for valve clearance)

- Timing chain lock tools (optional but helpful)

- OBD2 scanner (Techstream for Toyota preferred)

- Cam/crank seal installer if rebuilding

📘 Want More?

I can provide:

- 📥 1NZ-FE full service manual (PDF)

- 🖼️ Timing chain diagram & VVT solenoid location

- 🛠️ Rebuild guide + parts list

- ✅ Diagnostic chart for codes or idle issues

- 💾 Printable torque spec cheat sheet

Toyota 1DZ engine repair manual PDF

Repairing the Toyota 1DZ engine, commonly used in Toyota forklifts, involves understanding its industrial diesel design—a 2.5L inline-4 indirect-injection engine. It’s known for durability, low-end torque, and simplicity, but like all engines, it faces wear from heavy industrial use.

🔧 Toyota 1DZ Engine Repair Overview

🔥 1. Hard Starting / No Start

- Symptoms: Cranking but not firing, white smoke.

- Common Causes:

- Weak glow plugs or faulty relay

- Injection timing off

- Air in the fuel lines

- Fix:

- Check and replace glow plugs (resistance < 1.0Ω).

- Bleed fuel system of air.

- Inspect and correct timing at the fuel pump.

- Check compression (should be 400+ psi).

💨 2. Excessive Smoke

| Smoke Color | Common Causes |

|---|---|

| Black | Overfueling, dirty air filter, bad injectors |

| Blue | Oil burning – valve seals or piston rings |

| White | Cold start, bad glow plugs, head gasket |

- Fix:

- Clean or replace air and fuel filters.

- Rebuild or clean injectors.

- Replace valve stem seals if oil burning on startup.

- Check for coolant loss = possible head gasket leak.

⚙️ 3. Fuel Injector Problems

- Symptoms: Rough idle, misfire, fuel knock.

- Fix:

- Remove and test injectors (atomization and spray pattern).

- Replace nozzle or complete injector if worn.

- Ensure correct injection pressure (approx. 180 bar / 2600 psi).

🧯 4. Overheating

- Causes: Clogged radiator, failing water pump, blown head gasket.

- Fix:

- Flush radiator and cooling passages.

- Inspect thermostat (or remove to test).

- Pressure test coolant system for leaks.

- Inspect cylinder head for cracks or warping.

⛓️ 5. Timing Belt/Chain

- The 1DZ usually uses a timing gear system (no belt), but:

- Check and adjust fuel pump timing if hard starting or smoke persists.

- Use timing marks on cam and pump sprockets.

🔩 Toyota 1DZ Torque Specifications

| Component | Torque Spec |

|---|---|

| Cylinder head bolts | 98 Nm + 90° |

| Connecting rod bolts | 54 Nm |

| Main bearing cap bolts | 98 Nm |

| Glow plug | 15 Nm |

| Injector hold-down clamp bolt | 27 Nm |

| Flywheel bolts | 127 Nm |

🔧 Regular Maintenance Intervals

| Task | Interval |

|---|---|

| Oil change | Every 250 hrs |

| Fuel filter replacement | 500 hrs |

| Air filter service | 250 hrs (or more in dusty areas) |

| Valve lash adjustment | 1000 hrs |

| Injector testing | 1500 hrs |

| Cooling system flush | Every 2 years |

🔧 Valve Clearance (cold engine)

- Intake: 0.25 mm (0.010 in)

- Exhaust: 0.35 mm (0.014 in)

🧰 Special Tools Needed

- Injector tester (pop tester)

- Valve spring compressor

- Torque wrench

- Compression tester (diesel)

- Feeler gauge

📘 Want More Help?

I can provide:

- 📥 Toyota 1DZ engine service manual (PDF)

- 🖼️ Exploded diagrams (injector, head, timing gears)

- 🔩 Full torque spec chart

- ✅ Rebuild checklist

- 💡 Diagnostic flowchart (no-start, smoke, overheat)

Toyota 1VD FTV engine repair manual PDF

Repairing the Toyota 1VD-FTV engine, Toyota’s only V8 turbo-diesel, requires both precision and a deep understanding of modern common rail diesel systems. This engine powers heavy-duty vehicles like the Toyota Land Cruiser 200 Series, 70 Series, and some Lexus variants. Known for torque, towing, and off-road reliability, the 1VD-FTV can still suffer from issues such as injector wear, turbocharger faults, EGR clogging, and overheating if not properly maintained.

🧰 TOYOTA 1VD-FTV ENGINE OVERVIEW

- Configuration: 4.5L V8 DOHC diesel

- Induction: Single or twin turbo (depending on variant)

- Fuel System: Common rail (Denso)

- Valvetrain: 32-valve, timing belt-driven camshafts

- Applications: Land Cruiser 200/70 Series, Lexus LX, military/off-road platforms

🔧 COMMON TOYOTA 1VD-FTV REPAIRS

🔥 1. Injector Failure

- Symptoms: Diesel knock, hard starting, excessive smoke, poor fuel economy

- Cause: Worn tips, incorrect pilot injection, poor fuel quality

- Fix:

- Replace or refurbish Denso injectors

- Replace copper washers and stretch bolts

- Relearn injector compensation codes using Techstream or equivalent

- ✅ Torque: Injector hold-down bolts – 8 Nm

💨 2. Turbocharger Issues

- Symptoms: Whining noise, power loss, black smoke, P0046 or P0299 codes

- Fix:

- Inspect VNT actuator (check for sticking or carbon buildup)

- Clean or replace the turbo

- Check boost solenoid, hoses, and MAP sensor

🌫️ 3. EGR & Intake Carbon Buildup

- Symptoms: Poor throttle response, limp mode, P0400/P0401 codes

- Fix:

- Remove and clean the EGR valve, cooler, and intake manifold

- Clean or replace MAP sensor

- Consider EGR blanking (off-road use only; check local laws)

⚙️ 4. Timing Belt Replacement

- Interval: Every 150,000 km (timing belt drives both camshafts)

- Replace:

- Belt

- Idlers

- Tensioner

- Water pump (if leaking)

- Crankshaft pulley bolt torque: 330 Nm (single-use bolt)

🔥 5. Cracked Pistons (early models: 2008–2012)

- Symptoms: Blow-by, knocking, oil consumption, low compression

- Fix:

- Remove cylinder heads, inspect for damage

- Replace pistons with updated OEM version (post-2012 design)

- May require full rebuild if cylinder walls are scored

🌡️ 6. Overheating

- Common Causes: Clogged radiator, failing viscous fan, cracked head gasket

- Fix:

- Replace coolant, test radiator

- Replace fan clutch

- Check for combustion gases in coolant (head gasket)

🔩 TORQUE SPECS – TOYOTA 1VD-FTV

| Component | Torque Spec |

|---|---|

| Cylinder head bolts | 25 Nm + 90° + 90° (sequence) |

| Injector clamp bolts | 8 Nm |

| Main bearing bolts | 130 Nm + 90° |

| Connecting rod bolts | 60 Nm + 90° |

| Camshaft bearing cap bolts | 14 Nm |

| Crankshaft pulley bolt | 330 Nm (use new bolt) |

| Flywheel bolts | 162 Nm |

| Glow plugs | 15 Nm |

🧪 DIAGNOSTICS

| Test / Sensor | Expected Value / Notes |

|---|---|

| Common rail pressure | ~30–160 MPa (idle to WOT) |

| Injector feedback value | ±3.0 mm³/st is normal |

| Compression (dry test) | 400–500 psi |

| EGR position sensor | Monitor with scan tool during operation |

| Turbo boost | ~15–20 psi (depending on variant) |

⚠️ COMMON DTC CODES (with possible fixes)

| Code | Meaning | Likely Cause |

|---|---|---|

| P0046 | Turbo actuator problem | VNT stuck, actuator faulty |

| P0400 | EGR flow malfunction | Dirty EGR or MAP sensor |

| P0299 | Turbo underboost | Leak, actuator, worn turbo |

| P0201–P0208 | Injector circuit fault | Wiring or injector failure |

| P1229 | Fuel overpressure | SCV, fuel pump, rail pressure too high |

🧰 SPECIAL TOOLS NEEDED

- Injector coding tool (Techstream / Snap-on / Launch)

- Torque angle gauge

- Pulley holder (for crankshaft bolt)

- Compression tester for diesel

- Denso diagnostic tools (if available)

📘 WANT MORE?

I can provide:

- 📥 1VD-FTV service manual (PDF)

- 🛠️ Rebuild checklist

- 🖼️ Exploded diagrams (injector system, turbo, timing belt)

- 🧪 Diagnostic tree for turbo, injector, or smoke problems

- ✅ Printable torque spec sheet