Toyota engine control module

Toyota Engine Control Module (ECM): The Brain Behind Performance and Efficiency

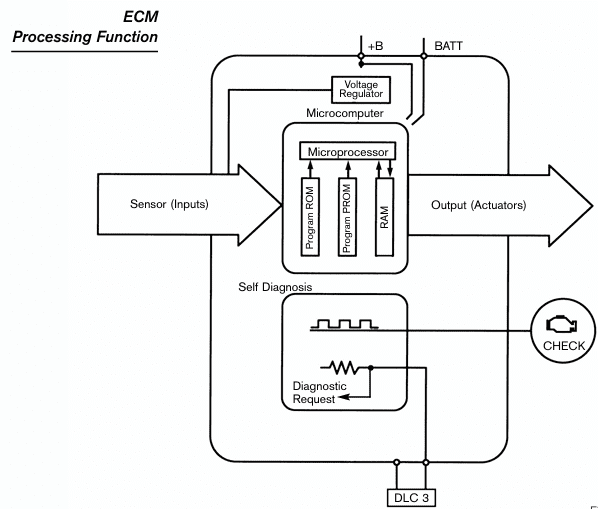

The Engine Control Module (ECM), sometimes interchangeably called the Engine Control Unit (ECU), is one of the most critical components in modern Toyota vehicles. Acting as the brain of the engine, the ECM is responsible for monitoring and controlling a wide range of functions related to the engine’s performance, emissions, and overall efficiency. As vehicle technology continues to evolve, the ECM has grown in complexity, transforming from a simple control device into a sophisticated computer that ensures vehicles meet modern expectations for performance, fuel economy, and environmental responsibility.

What Is the ECM and What Does It Do?

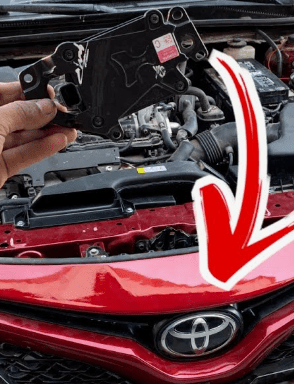

The ECM is a microprocessor-based system embedded within the vehicle, usually located in the engine bay or under the dashboard. It constantly receives input data from various sensors throughout the vehicle and adjusts the engine parameters accordingly. The ECM controls several key functions, including:

- Fuel Injection Timing and Quantity: By adjusting the amount and timing of fuel injected into the combustion chamber, the ECM ensures optimal combustion for efficiency and power.

- Ignition Timing: The ECM determines the ideal moment for the spark plug to ignite the fuel-air mixture to maximize power and minimize emissions.

- Air-Fuel Ratio Management: Maintaining the proper air-fuel mixture is essential for combustion, and the ECM dynamically adjusts this based on driving conditions.

- Idle Speed Control: The ECM manages engine idling by controlling airflow when the vehicle is stationary.

- Variable Valve Timing (VVT): In engines equipped with Toyota’s VVT-i (Variable Valve Timing with intelligence), the ECM modulates valve timing to enhance performance and fuel economy.

- Emissions Control: The ECM helps maintain compliance with emissions standards by managing exhaust gas recirculation (EGR), oxygen sensors, and catalytic converter efficiency.

Inputs and Outputs: Sensor and Actuator Network

To perform its duties effectively, the ECM relies on a network of sensors and actuators. These include:

Key Sensors:

- Mass Air Flow (MAF) Sensor

- Manifold Absolute Pressure (MAP) Sensor

- Oxygen (O2) Sensors

- Throttle Position Sensor (TPS)

- Crankshaft and Camshaft Position Sensors

- Coolant Temperature Sensor

- Knock Sensor

Actuators Controlled by the ECM:

- Fuel Injectors

- Ignition Coils

- Throttle Body Actuator

- Idle Air Control Valve

- EGR Valve

- Cooling Fan Relay

The ECM uses data from sensors to make real-time decisions, sending output signals to actuators to modify engine operation accordingly.

Toyota-Specific Technologies

Toyota has developed several proprietary systems that integrate tightly with the ECM. These include:

- Toyota VVT-i and Dual VVT-i: The ECM adjusts valve timing to optimize fuel economy or performance based on load and RPM.

- Toyota Hybrid Synergy Drive: In hybrid models like the Prius, the ECM works in coordination with additional control units to balance power from the gasoline engine and electric motor.

- Toyota D-4S Fuel Injection: A dual injection system using both direct and port injection, requiring precise ECM control for switching and blending.

Diagnostics and OBD Systems

The ECM also plays a vital role in On-Board Diagnostics (OBD-II), allowing technicians to detect and troubleshoot problems. When a fault occurs, the ECM stores a Diagnostic Trouble Code (DTC) and can trigger a Check Engine Light on the dashboard.

Toyota’s Techstream software, used by dealerships and certified technicians, can interface directly with the ECM to read live data, reset DTCs, and perform detailed diagnostics or software updates.

ECM Reprogramming and Flash Updates

Toyota, like many modern automakers, releases periodic software updates for ECMs. These updates can address drivability issues, improve fuel economy, or enhance compatibility with emissions requirements. Reprogramming is typically performed using factory scan tools and is becoming increasingly common in response to evolving environmental regulations and real-world driving data.

ECM Failure: Symptoms and Causes

While Toyota ECMs are generally reliable, failures can occur due to electrical surges, corrosion, or manufacturing defects. Common symptoms of a failing ECM include:

- Engine stalling or misfiring

- Poor fuel economy

- Check Engine Light illumination

- Difficulty starting or no start

- Loss of communication with diagnostic tools

In many cases, ECMs can be reprogrammed or replaced, but reprogramming must be done using correct procedures to avoid compatibility issues with the vehicle’s immobilizer system and other modules.

Future of ECMs in Toyota Vehicles – Toyota engine control module

As Toyota continues to innovate, especially in the areas of hybrid, electric, and hydrogen fuel-cell vehicles, ECMs will become even more advanced. Integration with Advanced Driver Assistance Systems (ADAS), vehicle-to-everything (V2X) communication, and cloud-based diagnostics will likely expand the ECM’s role from merely managing the engine to being a central node in an interconnected automotive ecosystem.

Toyota engine control module Overview

Below is an in‑depth look at the various types of Toyota Engine Control Modules (ECMs/ECUs), the major OEM and aftermarket brands that supply them, detailed pros & cons for each, and useful links to help you source the right unit for your vehicle.

1. Overview: What Is an ECM/ECU?

The Engine Control Module (ECM)—often called the Engine Control Unit (ECU) or, in full integration, the Powertrain Control Module (PCM)—is the computer that governs fuel delivery, ignition timing, emissions controls, idle speed, variable valve timing and (in hybrids) the interplay between gasoline engine and electric motor. Modern Toyota ECMs range from “basic” single‑engine controllers to multi‑processor units that coordinate hybrid drive, direct injection, and advanced diagnostics.

2. Key Types of Toyota engine control module Toyota ECMs

- Basic Fuel & Ignition ECUs

• Standard port‑injection engines (e.g. 1.8L‑2.0L 4‑cyl units)

• Controls fuel injector pulse width, spark timing, idle air control - VVT‑i / Dual VVT‑i ECUs

• Engines equipped with Variable Valve Timing with intelligence

• Dynamically alters camshaft phase to optimize power vs. economy - D‑4S (Direct‑Injection) ECUs

• Dual‑injection systems (port + direct) found in 2.0L‑2.5L engines (e.g. 2AR‑FE)

• Manages high‑pressure fuel pump, injector staging, and injection timing - Hybrid Synergy Drive (HSD) ECMs

• Prius/Lexus hybrids—coordinate gasoline engine, electric motor, generator, battery management

• Often paired with separate Power Control Units (PCUs) - Turbo & Forced‑Induction ECUs

• Found in GR variants (e.g. 1.6L‑1.8L turbo engines)

• Controls boost pressure, wastegate, intercooler fans, plus all standard functions

3. Major ECM Brands & Detailed Reviews -Toyota engine control module

3.1 Denso (Toyota OEM Supplier)

Denso is Toyota’s in‑house OEM partner for virtually all ECMs.

- Compatibility & Fit: 100% plug‑and‑play; exact same calibration, connectors, and housing as factory.

- Reliability: Built to Toyota’s stringent quality standards; typically outlasts the vehicle’s life.

- Aftermarket Support: Genuine Toyota stores, official parts websites, and authorized resellers.

- Drawback: Higher price point (often 50–100% more than aftermarket).

- Helpful Links:

- Toyota Genuine Parts ECM lookup:

https://autoparts.toyota.com/products/computer-engine-control - Denso direct catalog:

https://www.denso-am.eu/en/service/pccatalogue

- Toyota Genuine Parts ECM lookup:

3.2 Bosch

Bosch supplies ECUs for a vast range of automakers, including select Toyota applications.

- Technology: Often features more advanced processors and built‑in self‑diagnostics.

- Calibration: May require custom tuning or “flashing” to match Toyota engine maps exactly.

- Durability: Good overall, but some users report occasional software mismatches on older Toyotas.

- Price: Mid‑range—cheaper than OEM Denso but pricier than many budget brands.

- Helpful Links:

- Bosch Automotive Aftermarket:

https://www.boschautoparts.com/ - Bosch ECU search tool:

https://www.boschautoparts.com/en/auto-parts/ecm

- Bosch Automotive Aftermarket:

3.3 Hitachi Automotive Systems

Hitachi provides ECUs primarily for Nissan and Mitsubishi, but also supplies some Toyota models.

- Strengths: Sturdy hardware; good for high‑heat, under‑hood environments.

- Weaknesses: Less common for Toyota, so cross‑referencing part numbers is critical.

- Helpful Links:

- Hitachi Automotive Catalog:

https://www.hitachi-automotive.com/cftc/

- Hitachi Automotive Catalog:

3.4 Delphi Technologies

Delphi offers cost‑competitive aftermarket ECUs.

- Pros: Affordable, readily available online.

- Cons: Mixed reviews—some units exhibit sluggish throttle response or poor cold‑start behavior.

- Tip: Look for units with Toyota‑specific calibration files included.

- Helpful Links:

- Delphi Online Catalog:

https://www.delphiautoparts.com/

- Delphi Online Catalog:

3.5 ACDelco

ACDelco is GM’s parts arm but produces universal and model‑specific ECUs that fit Toyotas.

- Reprogramming Required: Most units ship blank or with generic GM tune; must be reflashed for Toyota protocols.

- Use Case: Enthusiasts doing engine swaps or people seeking a budget blank ECU for custom tuning.

- Helpful Links:

- ACDelco ECM/ECU Catalog:

https://www.acdelco.com/parts/electrical-control

- ACDelco ECM/ECU Catalog:

4. OEM vs. Aftermarket: Which Should You Choose?

| Feature | OEM (Denso/Toyota) | Aftermarket (Bosch/Delphi/etc.) |

|---|---|---|

| Fit & Finish | Exact factory spec | May need adapters or rewiring |

| Calibration | Pre‑loaded with vehicle‑specific map | Often generic; requires flashing |

| Warranty | 12‑36 month OEM warranty | Varies (6‑24 months) |

| Price | $$$ (high) | $–$$ (moderate to low) |

| Long‑term Support | Guaranteed through dealer network | Dependent on third‑party availability |

- When to go OEM: Vehicle under factory warranty, you need absolute reliability, or swapping same‑for‑same.

- When aftermarket makes sense: Out‑of‑warranty cars, custom performance builds, or tight budgets—but budget time for programming.

5. Programming & Installation – Toyota engine control module

- Part Number Verification

– Always cross‑check the five‑ or six‑digit Toyota part number (e.g. 89661‑0ZR02) against your chassis/VIN. - ECU Flashing Tools

– Toyota Techstream (dealer‑level tool) for Denso units

– Open‑source tuners (e.g. RomRaider, EcuTek) for aftermarket units - Professional Shop

– Many ECM installs require bench‑flash programming to load your exact VIN, immobilizer codes, and engine map. - Testing & Break‑In

– After installation, clear all Diagnostic Trouble Codes (DTCs) and perform a road‑test to verify smooth idle, throttle response, and proper O₂ sensor readings.

6. More Helpful Resources about Toyota engine control module.

- Toyota Techinfo (Service Manuals & ECM Pinouts):

https://techinfo.toyota.com/ - ECU removal & installation guides:

https://www.toyotanation.com/ – Search “ECU swap” - Aftermarket Tuning Communities:

– RomRaider Forums: https://www.romraider.com/

– EcuTek Tuning: https://www.ecutek.com/

Choosing the right ECM can make the difference between a flawless engine operation and frustrating drivability issues. Whether you stick with Denso/Toyota OEM for guaranteed fit and function or venture into Bosch/Delphi territory for cost savings and tuning potential, always verify part numbers, plan for proper programming, and source from a reputable supplier. Feel free to ask if you need help matching your exact Toyota model and engine!

Toyota engine control module Course PDF

Conclusion

Toyota’s Engine Control Module is a foundational technology that keeps the engine running smoothly, efficiently, and cleanly. From managing fuel and ignition to enabling emissions compliance and hybrid integration, the ECM serves as the brain that coordinates a symphony of mechanical and electronic systems. With increasing reliance on software-driven vehicles, the ECM will remain a crucial player in Toyota’s drive toward cleaner, smarter mobility.