Repairing a Toyota Corolla head gasket can range from a medium-level DIY project to a full professional engine job — depending on your tools, skills, and the model/year of the Corolla.

Below is a clear, mechanic-style guide with the steps, tools, torque specs, and tips that apply to most modern Corolla engines (1ZZ-FE, 2ZR-FE, and similar).

1. Symptoms of a Blown Head Gasket

Before diving in, confirm it’s actually the gasket:

- White exhaust smoke (coolant burning).

- Overheating / coolant loss with no visible leak.

- Bubbles in the radiator or overflow.

- Oil contaminated with coolant (milky color).

- Coolant contaminated with oil.

- Compression loss on one or more cylinders.

2. Tools & Supplies

Tools:

- Full metric socket set (8–19 mm) + torque wrench (inch-lb and ft-lb ranges).

- Breaker bar, extensions, swivel joint.

- Screwdrivers & pliers.

- Gasket scraper or plastic razor blades.

- Engine hoist optional (for easy head handling).

- Feeler gauges & straight edge (to check head warp).

- Drain pans, shop rags.

Parts & consumables:

- OEM head gasket set (includes valve cover, intake, exhaust, cam seals, etc.).

- New head bolts (most Toyota engines use torque-to-yield bolts — do not reuse).

- Engine oil + filter.

- Coolant.

- RTV silicone (Toyota FIPG for corners).

- Brake cleaner / degreaser.

3. Preparation

- Park on level ground, disconnect negative battery cable.

- Drain coolant and oil.

- Label & disconnect all wiring harnesses, hoses, and fuel lines attached to the head.

- Remove air intake assembly, exhaust manifold heat shield, and accessory drive belts.

- Remove timing cover and set engine to Top Dead Center on cylinder #1.

4. Disassembly Steps

- Remove valve cover.

- Remove timing chain/belt (depends on year — most post-2003 Corolla use a chain).

- Unbolt camshaft caps and remove camshafts.

- Remove intake & exhaust manifolds (can be done on engine or after head removal).

- Loosen head bolts in reverse torque sequence to prevent warping (outer to inner).

5. Head Removal & Inspection

- Lift cylinder head straight up — avoid prying against sealing surfaces.

- Remove old gasket and clean block surface with a plastic scraper — avoid gouging aluminum.

- Check head with straight edge & feeler gauge — Toyota spec usually max warp 0.05 mm (0.002″) across length/width. If warped, resurface at a machine shop.

- Inspect for cracks (especially between valves) — pressure test if possible.

6. Installation

- Clean head bolt holes in block — blow out with compressed air.

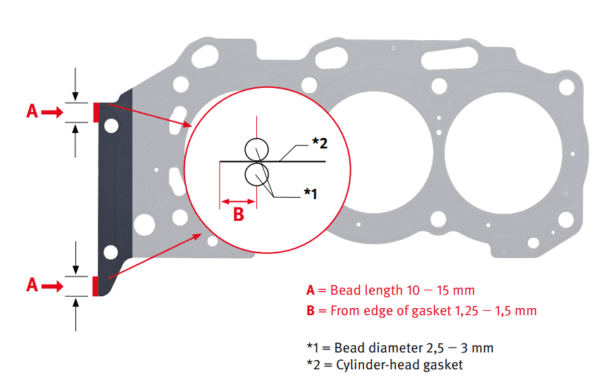

- Place new head gasket on block, aligned with dowels (metal side up if one side is coated).

- Carefully lower head onto block — align dowels.

- Install new head bolts, lubricating threads with light oil.

7. Torque Specs (example: 1ZZ-FE engine)

(Always check your Corolla’s exact FSM — values vary by year/engine)

Head bolts:

- Step 1: Torque all bolts to 36 ft-lb in sequence.

- Step 2: Tighten all bolts an additional 90°.

- Step 3: Tighten all bolts an additional 90° again.

Tightening sequence: start in center, work outwards in spiral pattern.

8. Reassembly

- Reinstall camshafts, torque cam caps to spec (~12–14 ft-lb).

- Install timing chain/belt & set timing marks correctly.

- Refit manifolds, torque to spec (intake ~15–21 ft-lb, exhaust ~27–30 ft-lb).

- Install valve cover with new gasket + RTV in timing cover corners.

- Reconnect wiring, hoses, and accessories.

- Fill with fresh oil & coolant.

9. First Start & Break-in

- Start engine, let idle until warm — check for leaks.

- Bleed cooling system (Toyota uses a high fill point — keep heater on HOT).

- Re-torque if FSM specifies (most torque-to-yield bolts do not require re-torque).

- After ~500 km (300 mi), check oil/coolant levels again.

10. Cost & Time Estimates

- DIY parts: $150–$400.

- Machine shop head resurfacing: $60–$150.

- Labor (shop): $900–$1,600+ depending on model.