P0335 Toyota – CRANKSHAFT POSITION SENSOR A

CIRCUIT

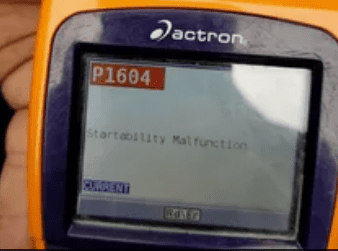

DTC P0335: Crankshaft Position Sensor Circuit Malfunction (Toyota)

Description

This code indicates an issue with the crankshaft position sensor or its circuit. The crankshaft position sensor provides the engine control module (ECM) with the rotational speed and position of the crankshaft, which is critical for ignition timing, fuel injection, and other engine functions.

Possible Causes of P0335

- Faulty Crankshaft Position Sensor

- The sensor may be damaged or have internal electrical issues.

- Wiring or Connector Problems

- Open or shorted wires in the crankshaft sensor circuit.

- Corrosion or damage to the sensor connector.

- Faulty Reluctor Ring

- A damaged or misaligned reluctor ring on the crankshaft can cause incorrect readings.

- ECM Issues

- A malfunction in the ECM could prevent it from properly interpreting sensor signals.

- Battery Voltage Problems

- Low battery voltage or charging system issues can disrupt sensor performance.

Symptoms of P0335 Toyota

- Check Engine Light (CEL):

- The most common indicator of this DTC.

- Engine Stalling or No Start:

- The engine may stall unexpectedly or fail to start altogether.

- Poor Engine Performance:

- Rough idling, reduced power, or misfires may occur.

- Erratic Tachometer Readings:

- The tachometer may behave abnormally due to incorrect sensor data.

Diagnosis Steps

- Retrieve and Confirm Codes:

- Use an OBD-II scanner to verify the presence of P0335.

- Check for other related codes, such as P0340 (camshaft position sensor).

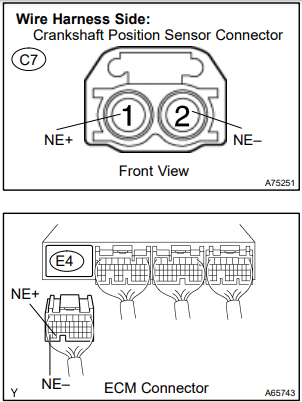

- Inspect Wiring and Connectors:

- Look for damage, corrosion, or loose connections in the sensor circuit.

- Ensure the wiring harness is not pinched or melted.

- Check the Crankshaft Position Sensor:

- Use a multimeter to measure the sensor’s resistance and output voltage.

- Compare the readings to manufacturer specifications.

- Inspect the Reluctor Ring:

- Verify that the reluctor ring is intact, properly aligned, and free of debris.

- Test the ECM:

- If all other components are functioning correctly, test the ECM’s ability to process the sensor signal.

Repair and Fixes

- Replace the crankshaft position sensor if it is defective.

- Repair or replace damaged wiring or connectors.

- Realign or replace the reluctor ring if necessary.

- Replace the ECM if it is confirmed to be at fault.

Additional Tips

- After repairs, clear the DTC using an OBD-II scanner and test drive the vehicle to ensure the issue is resolved.

- Use OEM or high-quality replacement parts to ensure proper operation.