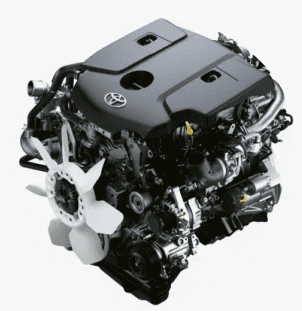

2UZ FE torque specs

Here are the key torque specifications for the Toyota 2UZ‑FE V8 (4.7 L) engine, based on factory and verified third-party sources. This includes fastener values for the main structural and mechanical components—targeting rebuilds, top-end work, or general engine service:

🧱 Cylinder Head Bolts

- Step 1: 24 ft‑lb (33 N·m)

- Step 2 & 3: Turn each bolt +90°, then another +90° (total +180°) (forum.ih8mud.com)

This torque-to-yield sequence is critical—especially for 2000–2009 models—and avoids overtightening. Always use new head bolts. (torkspec.com)

🏗️ Main (Crankshaft) Bearing Cap Bolts

- Step 1: 20 ft‑lb (27 N·m)

- Step 2: Turn each bolt +90° (torkspec.com)

🔩 Connecting Rod Cap Bolts

- Step 1: 18 ft‑lb (24 N·m)

- Step 2: Turn each bolt +90° (charm.li)

⚙️ Camshaft Timing Tube Center Bolt

- Torque to 58 ft‑lb (79 N·m) (torkspec.com)

🔧 Intake & Exhaust Manifolds

- Intake manifold bolts: 13 ft‑lb (18 N·m) (rodsshop.org)

- Exhaust manifold nuts: 32 ft‑lb (44 N·m) (rodsshop.org)

🛢️ Oil System

- Oil drain plug: 29 ft‑lb (39 N·m) (rodsshop.org)

- Oil filter housing/drain plug: 9 ft‑lb (12 N·m)

- Oil pan bolts:

- Lower bolts: 6 ft‑lb (7 N·m)

- Upper bolts: 6–21 ft‑lb (7–29 N·m), depending on bolt size (rodsshop.org)

- Oil pick-up tube: 6 ft‑lb (8 N·m) (rodsshop.org)

- Oil pump mounting:

- 12 ft‑lb (16 N·m) for 12 mm bolts

- 23 ft‑lb (31 N·m) for 14 mm bolts

- Oil pump body cover: 7 ft‑lb (10 N·m) (rodsshop.org)

🔁 Drive / Flexplate & Pulleys

- Flexplate to crankshaft:

- Step 1: 22 ft‑lb (30 N·m)

- Step 2: +90° (rodsshop.org, forum.ih8mud.com)

- Flexplate to torque converter: 35 ft‑lb (48 N·m) (rodsshop.org)

- Crankshaft pulley bolt: 181 ft‑lb (246 N·m) (rodsshop.org)

⏱️ Timing & Accessory Bolts

- Camshaft sprocket/timing tube pulleys/clutch: 6 ft‑lb (8 N·m)

- Timing chain guides/damper bolts: 15 ft‑lb (20 N·m) (rodsshop.org)

- Timing belt/idler/tensioner bolts: 26 ft‑lb (35 N·m) for idler; 12–19 ft‑lb (16–26 N·m) for tensioners

- Drive belt tensioner: 12 ft‑lb (16 N·m)

🔍 Valve Cover & Miscellaneous

- Valve cover bolts: 7 ft‑lb (10 N·m) (rodsshop.org)

- Spark plugs: 13 ft‑lb (18 N·m)

✅ Summary Table

| Component | Torque | Additional Steps |

|---|---|---|

| Cylinder head bolts | 24 ft‑lb (33 N·m) | +90° +90° angle-tighten |

| Main bearing cap bolts | 20 ft‑lb (27 N·m) | +90° angle-tighten |

| Connecting rod bolts | 18 ft‑lb (24 N·m) | +90° angle-tighten |

| Crankshaft pulley bolt | 181 ft‑lb (246 N·m) | — |

| Flexplate → crankshaft | 22 ft‑lb (30 N·m) | +90° |

| Flexplate → torque converter | 35 ft‑lb (48 N·m) | — |

| Cam timing tube center bolt | 58 ft‑lb (79 N·m) | — |

| Intake manifold bolts | 13 ft‑lb (18 N·m) | — |

| Exhaust manifold nuts | 32 ft‑lb (44 N·m) | — |

| Oil pan bolts (10 ± 12 mm) | 6 ft‑lb (7 N·m) | — |

| Oil pick-up tube | 6 ft‑lb (8 N·m) | — |

| Oil pump mounting bolts | 12–23 ft‑lb (16–31 N·m) | — |

| Oil drain plug | 29 ft‑lb (39 N·m) | — |

| Valve cover bolts | 7 ft‑lb (10 N·m) | — |

| Spark plugs | 13 ft‑lb (18 N·m) | — |

🛠️ Best Practices

- Always use a calibrated torque wrench, especially for low-torque specs.

- Replace torque-to-yield bolts (head, main, rod) with new OEM parts.

- Follow angular-tightening precisely—mark bolts and track rotations.

- Lubricate threads with clean engine oil for accuracy.

- Tighten in proper sequence, particularly on head and bearing caps—always refer to service manual diagrams.