2002 Toyota Echo engine torque specifications

Here are the official engine torque specifications for the 2002 Toyota Echo (1NZ‑FE 1.5 L engine), based on service manual figures and professional rebuild data:

⚙️ Cylinder Head Bolts

- Step 1: Tighten all 10 head bolts to 29.4 N·m (300 kgf·cm, 22 ft·lbf).

- Step 2: Rotate each bolt an additional 90°, then another 90°—totaling +180° after initial torque (justanswer.com, scribd.com).

Tip: Mark each bolt as you rotate, to ensure correct sequencing and avoid uneven clamping .

🔩 Connecting Rod Cap Bolts

- First pass: 15 N·m (150 kgf·cm, 11 ft·lbf)

- Second: Rotate an additional 90° (caphector.com).

Mechanic-recommended: apply light engine oil on threads and under the head, and tighten by hand for even clamping (justanswer.com).

📌 Camshaft Bearing Cap Bolts

- No. 1 bearing cap (center): 23 N·m (235 kgf·cm, 17 ft·lbf)

- No. 2 bearing cap: 12.7 N·m (130 kgf·cm, 10 ft·lbf) (caphector.com).

These are stepped—tighter on the center cap for proper camshaft alignment.

⚙️ Camshaft Sprocket & Timing Control

- Cam sprocket bolt: 64 N·m (650 kgf·cm, 47 ft·lbf) (caphector.com).

- Valve timing controller (VVT) and cam sprocket assembly bolts: also 64 N·m (650 kgf·cm, 47 ft·lbf) (caphector.com).

💨 Intake and Exhaust Manifolds

- Intake manifold: 30 N·m (300 kgf·cm, 22 ft·lbf) (caphector.com)

- Exhaust manifold: 27 N·m (275 kgf·cm, 20 ft·lbf) (caphector.com)

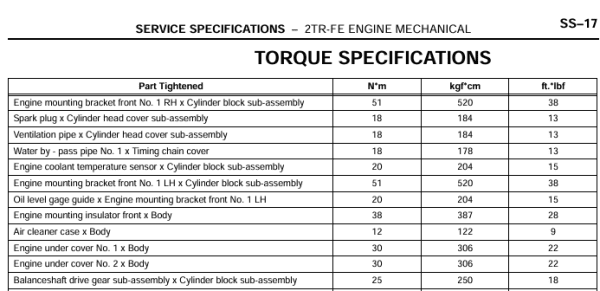

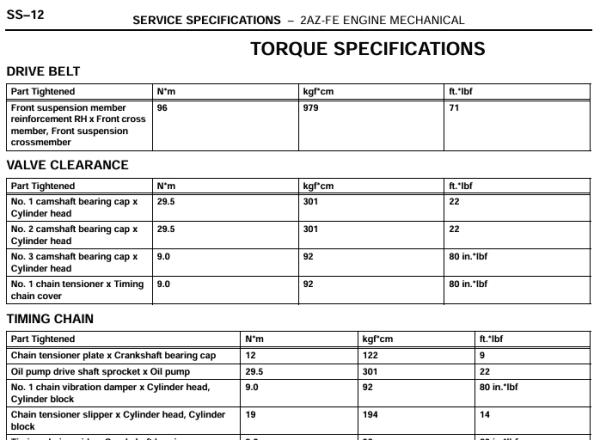

⛓️ Timing Cover & Chain Tension Components

- Timing chain cover bolts: A, C, D positions—11 N·m (100 in·lbf / 8 ft·lbf); B, E, etc.—24 N·m (245 kgf·cm, 18 ft·lbf) (caphector.com).

- Chain vibration damper & tensioner: 9.0 N·m (80 in·lbf) (caphector.com).

🛢️ Oil System & Pans

- Oil pan (No. 1): 24 N·m (245 kgf·cm, 18 ft·lbf) (caphector.com)

- Oil pan No. 2: 9.0 N·m (80 in·lbf) (caphector.com)

- Oil strainer to pan: 11 N·m (112 kgf·cm, 8 ft·lbf) (caphector.com)

- Oil pump cover & plug bolts: 9–11 N·m (80–110 in·lbf)

🌀 Other Critical Fasteners

- Crankshaft pulley bolt: 128 N·m (1,300 kgf·cm, 94 ft·lbf) (caphector.com)

- PCV valve to head cover: 27 N·m (275 kgf·cm, 20 ft·lbf) (caphector.com)

- Coolant/water pump and drain/filler bolts: 9–15 N·m range

- Engine mounting bolts and hangers: vary from 38–64 N·m

✅ Torque Procedure Summary

- Pre-lube all bolt threads with clean engine oil for accuracy.

- Follow torque sequence especially for head bolts (cross patterns) and rod caps (alternating).

- Multi-step tightening: Apply initial torque, then angular rotation, where specified.

- Retorque/inspect after assembly run-in, particularly for head bolts and rod caps.

📚 References & Further Reading

- Official 2002 Echo Service Manual (Engine Mechanical Section) – full torque table (scribd.com, caphector.com)

- Professional rebuild insight (JustAnswer): rod caps ~15 N·m + 90° (ww2.justanswer.com)

- Detail on head bolt sequence/technique (Scribd) (scribd.com)

🛠️ Practical Tips

- Head bolts are torque-to-yield (TTY)—they stretch, not just bend. Always use new bolts, and torque to spec in the correct sequence .

- Cam and rod fasteners handle less torque, careful not to overtighten.

- Mark bolts after angle tightening for confirmation.

- Use a calibrated torque wrench—easy to miss small N·m values like 9–11 N·m.